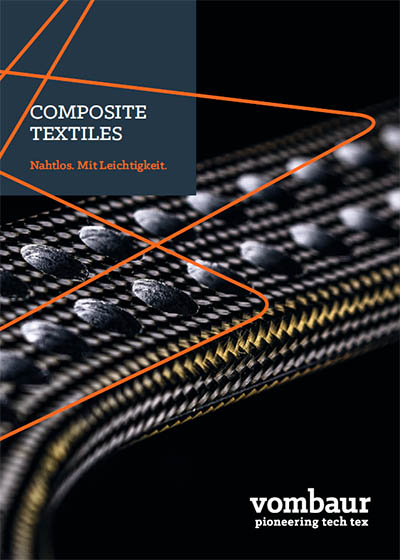

COMPOSITE TEXTILES

Low weight – high strength: Composites by vombaur

Lightweight components made of vombaur fabrics – stronger than metal and yet extremely light: these are composites made of seamlessly woven high-performance fibres and special resin systems.

High-strength textile composite materials made of carbon, aramid, glass, and hybrids

Round woven tubulars and woven 3D textiles: the fibres of our composite fabrics made of carbon, aramid, glass and hybrids are seamlessly woven. This ensures the exceptional strength and high stiffness. After all, vombaur 3D woven fabrics are formed without seam or weld contours. There are no undesirable break points with us.

Light weight, perfect fit, high rigidity: form-woven composites

Aviation, automotive, mechanical engineering, electronics, medical technology and much more. In many industries, parts need to be just as lightweight as they are capable of bearing loads. You can rely on our composite fabrics. And we offer an impressive variety of forms: flat woven fabrics, round woven tubulars, 3D woven fabrics, spiral woven fabrics and preforms in the most diverse geometries.

Composite textiles to your specifications

| Material | Carbon, aramid, glass, hybrids |

| Fineness | Carbon: 1 K to 48 K Glass: 11 tex to 1200 tex |

| Fibres | Multifil, twisted |

| Width | Standard: up to 350 mm Custom-made products: up to 950 mm |

| Weaving Technique | Needle or shuttle technology |

| 3D-Profile and chamber systems | T, double T, star shape, hollow chamber structures, omega profiles |

| Binding | Taffeta, twill, satin, special bindings |

| Finishing | Powder-coated, non-woven coated, hot melt adhesive component |

| Custom manufacture | With two identical selvedges, with elasticated weft |

| Assembly | Preform, delivered as kit, custom designs |

Composite textiles to your specifications

Material

Carbon, aramid, glass, hybrids

Fineness

Carbon: 1 K to 48 K

Glass: 11 tex to 1200 tex

Fibres

Multifil, twisted

Width

Standard: up to 350 mm

Custom-made products: up to 950 mm

Weaving Technique

Needle or shuttle technology

3D-Profile and chamber systems

T, double T, star shape, hollow chamber structures, omega profiles

Binding

Taffeta, twill, satin, special bindings

Finishing

Powder-coated, non-woven coated, hot melt adhesive component

Custom manufacture

With two identical selvedges, with elasticated weft

Assembly

Preform, delivered as kit, custom designs

Unique composite materials made of textiles and resin systems

Numerous applications in a wide variety of industries

We are happy to help you with our composite textiles. Simply contact us.

Contact person

Johannes Kauschinger

Sales Manager